DX52D Galvanized coil

Classification :

Keywords:

DX52D Galvanized coil

DX52D galvanized coil is a surface galvanized sheet with yield strength of 235MPa.

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

|

DX52D Galvanized coil |

|

|

Manufacturer JIS DIN high-quality electro-galvanized steel coil |

|

|

Product name: |

DX52D Galvanized coil |

|

Place of Origin: |

China |

|

Type: |

Steel Coil |

|

Standard: |

AISI, ASTM, BS, DIN, GB, JIS |

|

Certificate: |

ISO9001 |

|

Grade: |

SPCC,SPCD,SPCE/DC01.DC02.DC03/ST12,Q195 .Etc |

|

Thickness: |

0.1-5.0mm |

|

Surface structure: |

anti-finger print /skin pass/oiled/ dry/chromated |

|

Size: |

Customized according to customer needs |

|

Tolerance: |

±1% |

|

Processing Service: |

Bending, Welding, Decoiling, Cutting, Punching, Welding |

|

Invoicing: |

by actual weight |

|

Delivery Time: |

7-15 days |

|

Technique: |

Hot Rolled Based, Cold Rolled |

|

Port: |

Tianjin Qingdao or according to your requirement |

|

Packaging Details |

in bundles, in bulk, customized packing. |

Warehouse Storage

Jiangsu Hongtu Metal Technology Co., Ltd. was established in 2009, located in Jiangsu Province with our own factories of 20000 m2. We have passed the "ISO9001 quality system certification, and EU CE certification". In 2018, Jiangsu Hongtu Metal Technology Co., Ltd. was rated as "Jiangsu High-tech Enterprise".With more than 3,000 independent patents, the annual output of steel products exceeds 6 million tons, and the inventory exceeds 250,000 tons.

Packing and shipping

Our company is a large steel manufacturer located in Jiangsu, the collection of processing and trading.And we have high supply ability. In 2011, we opened the market to the abroad. products are exported to Europe, the United States, the Middle East, India and other countries.

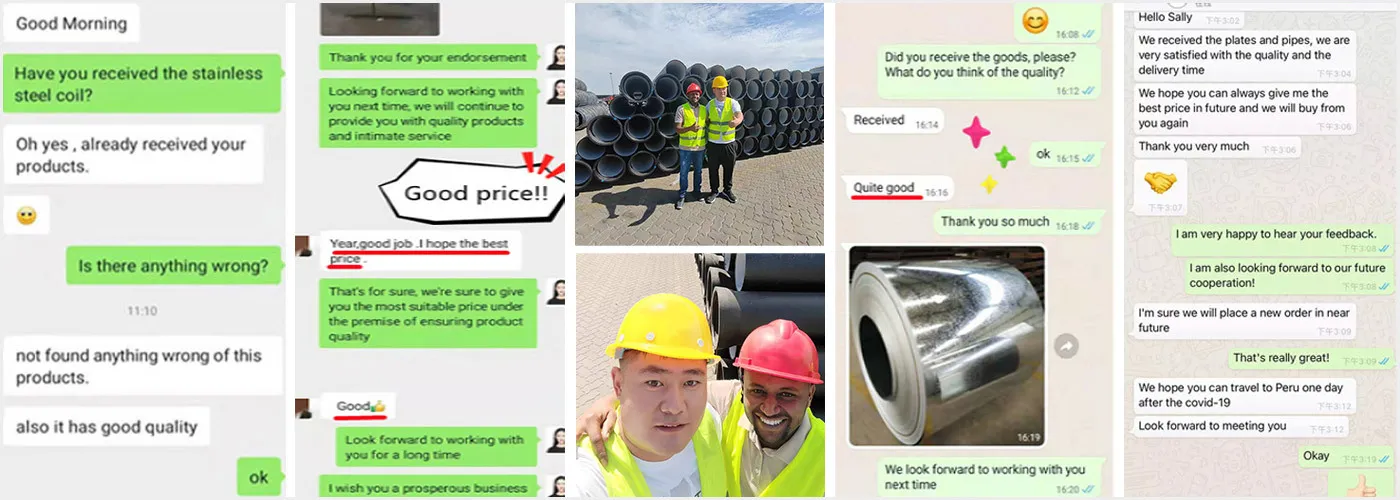

Customer conversation

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective.

Application field

Our main products are carbon steel, stainless steel, galvanized steel, etc. which are suitable for engineering, coal mining, textile, electric power, boilers, machinery, military industry and other fields.

FAQ

Honor

RELATED PRODUCTS

GET A FREE QUOTE